Organic Shoyu Soy Sauce

Mitoku’s shoyu is made with just four simple ingredients: whole soybeans, whole wheat, sea salt, and water. The quality of the soybeans is of defining importance, as these provide the basis for the sauce itself. For this reason, we use protein-rich whole soybeans, whereas most other soy sauces on the market are made with defat-processed soybeans.

Mitoku only works with producers who use traditional techniques and do not use artificial additives such as alcohol as preservatives. These techniques center around three key processes: koji-making, fermentation, and maturation. Of these, the koji-making is of special importance because koji is very rich in enzymes, which break down the raw ingredients and drive the critical fermentation process. This powerful yet delicate microbial culture needs optimal conditions to thrive, and creating the right environment requires experience and careful supervision.

Another key element is the use of wooden vats. These provide the perfect, microorganism-rich environment for the koji-generated enzymes to work their magic over a long period of fermentation and maturation. Every batch of Mitoku’s superlative shoyu can bring out the best in even simple dishes, whatever the ingredients or cuisine.

Mitoku uses GMO-free whole soybeans

There is a world of difference between Mitoku organic soy sauces and most other products on the market. The biggest difference is in the raw ingredients. Today, about 80% of the soy sauce produced in Japan uses processed soybeans, which are cheaper, easier to transport, and allow for quicker fermentation than whole soybeans. Mitoku, by contrast, uses only whole soybeans, which provide the full nutritional content of the soybean and take longer to ferment, resulting in a full flavored sauce loaded with umami-rich amino acids. As Mitoku opposes the proliferation of genetically engineered foods, all of our ingredients are GMO-free.

Celebrating regional diversity

Shoyu was already indispensable to Japanese cuisine hundreds of years ago, when means of transport were still scarce in Japan. As a result, each region developed its own unique version of the sauce. At Mitoku, we honor this diversity by providing organic soy sauces from a variety of renowned manufacturing regions.

Organic Smoked Soy Sauces

These sensational smoked soy sauces are new additions to our range. Made using a special patented process by smoking Mitoku Organic Shoyu or Organic Tamari over Japanese cherry wood, these sauces are infused with dramatic and intense flavors, transforming them into exciting, new taste experiences.

These sensational smoked soy sauces are new additions to our range. Made using a special patented process by smoking Mitoku Organic Shoyu or Organic Tamari over Japanese cherry wood, these sauces are infused with dramatic and intense flavors, transforming them into exciting, new taste experiences.

You can discover the best way to use these new sauces by using them in place of regular soy sauce to taste the difference, then experimenting with any dish you like, such as sushi, grilled dishes, or even smoked foods. Their powerful flavor and aroma mean just a few drops will be enough to enhance any dish.

Mitoku’s shoyu is made with just four simple ingredients: whole soybeans, whole wheat, salt, and water. Through fermentation, these ingredients are transformed into a delicious seasoning with an appetizing aroma and deep, rich color. Each ingredient plays its own special role. The protein content of the whole soybeans supplies umami, while the whole wheat gives the sauce its sweetness and distinctive fragrance. The salt works to protect the shoyu from bacteria during fermentation. Pure, fresh water is also required to produce a good quality sauce.

Traditionally produced shoyu is the result of a series of carefully controlled processes, namely preparation, koji-making, fermentation, maturation, pressing, heating, filtering, and bottling. Some of the key processes are outlined below.

Koji-making

This stage is perhaps the most critical, as it will shape the taste and quality of the entire batch. You cannot make good shoyu without good koji.

First, whole soybeans are soaked in water, then steamed. The producers must rely on their years of experience to determine the optimal volume of water and degree of steaming. Once steamed, the soybeans are mixed with roasted wheat, inoculated with the koji spores (Aspergillus oryzae), and stored in a special incubation chamber for a few days to allow the culture to propagate. The temperature and humidity of the room is carefully monitored and controlled to ensure that the resulting koji is fit for its task, which is to kick-start the fermentation process.

Fermentation and maturation

The next stage is to transfer the koji to large wooden tanks and add salted water. The salt halts the propagation of the koji, and instead the enzymes generated by the koji get to work on breaking down the whole soybeans and whole wheat. The fermentation environment is rich with microorganisms, including lactic acid bacteria and yeast, and each of these also plays its role in the fermentation process. With the ingredients now broken down, the shoyu is left to mature, allowing it to slowly develop the rich flavor, deep color, and complex aroma that is characteristic of Mitoku Shoyu.

Since living microorganisms drive this stage of production, the shoyu can differ slightly from batch to batch. Consistency can be achieved, however, through the expertise of the producer. This can be done, for example, by deciding when the mixture should be stirred, a process that supports the work of the microorganisms, and by keeping a watchful eye on the mixture, making adjustments according to changes in weather or temperature. The exact length of the fermentation and maturation process will depend on the producer’s judgement. Once the batch is considered ready, the sauce is pressed, heated, filtered, and finally bottled.

Traditional shoyu can serve to enhance and deepen flavor in any type of cooking.

This versatile condiment can be used with any cuisine at any stage of cooking, be it preparation, during cooking, or at serving, bringing an appetizing aroma, depth of flavor, and color to almost any dish. This is down to shoyu’s unique balance of the five basic tastes: sweet, sour, salty, bitter, and umami. This balance comes from the sauce’s base ingredients and the long process of fermentation and maturation.Show more...

Related Recipes

-

Brussel Sprouts

-

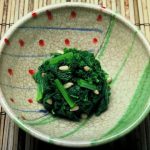

Greens with Japanese Vinaigrette

-

Tofu in a Blanket

-

Nara-Style Tempura Dip Sauce (Vegetarian)

-

Somen on Ice

-

Clear Gravy

-

Noodles in Broth

-

Hot and Spicy Chinese Noodle Soup

-

Sushi Ginger Rolls

-

Wasabi Guacamole

-

Baked Yellow Squash (“Squash Fish”)

-

Sushi Roll (Futomaki)

-

Zaru Udon

-

Poached Shrimp

-

Sesame Ginger Miso Dressing

-

Teriyaki Tofu

-

Tempura with Tempura Dip Sauce

-

Soy Sauce Flavored Pasta with Mushrooms

-

Teriyaki Grilled Seasonal Vegetables

-

Dried Daikon Pickles

-

Lotus Root with Carrot & Burdock

-

Kukicha Tonics: Sho-Ban

-

Kukicha Tonics: Ume-Sho-Ban

-

Shrimp Japonais

-

Arame with Lotus Root

-

Hijiki Summer Salad

-

Ginger Fried Rice

-

Seitan Stew

-

Shiitake Gravy

-

Seitan Bourguinonne

-

Nori Maki (Sushi Nori Rolls)

-

Braised Gingered Broccoli

-

Somen with Maitake Spinach

-

Hearty Baked Vegetables

-

Vinegared Land and Sea Vegetables

-

Kombu Shoyu Pickles

-

Hijiki with Dried Tofu and Vegetables

-

Arame with Fried Tofu

-

Pan-Fried Mochi

-

Summer Soba

-

Orange Roughy with Maitake and Onions

-

Noodle Rolls

-

Sesame Tofu

-

Avocado Sashimi

-

Spicy Soba Salad

-

Umeboshi Tea

-

Mochi Soup (O-zoni)

-

Clear Soup

-

Dried Tofu with Ginger

-

New England Boiled Dinner

-

Marinated Steamed White Fish Fillets

-

Scrambled Tofu