Preserving the Traditional Yaemon Flavour

Preserving the Traditional Yaemon Flavour

The Minamigura Aoki Yaemon Company, founded in 1871, is located in Taketoyo, Aichi Prefecture, a small town famed for its tamari. They are the only local company that is still producing traditional go-bu tamari, a thick, double-concentrate soy sauce made with ten parts soybeans to five parts water.

Ownership of this small, family firm has been passed down through the generations to its current owner, Yoshio Aoki (fifth generation), also known by his inherited title of “Yaemon”. The Aoki family’s relationship with Mitoku began with Yoshio’s father, Kōichirō Aoki, who initiated the production of organic tamari. Mitoku now exports this delicious and rare tamari to selected countries around the world, where it has received enthusiastic praise from, among others, Michelin three-starred chefs.

With Yaemon’s son, Yoshiyuki, now working together with his father, the fifth generation of the Aoki family is passing the techniques, knowledge, pride, and dedication of their ancestors on to the sixth. As Yaemon says, “My role is to protect a flavour that has been a tradition for 150 years. That is to say, I am faithfully replicating everything that has been done up until now.”

Yoshiyuki Aoki has also grown up with this attitude and from a young age never once doubted that he would take on the family business: “It’s the details that make up the big picture,” he says. “That’s what my father always says. When we produce something, we put all of our energy into making each detail as good as it can be. We repeat the same procedures every day, without slacking on any of the details. In this way, we work slowly and steadily, carrying out each step to the best of our abilities. I think that is the most important thing.” When Yoshiyuki eventually takes over the company, he will inherit his father’s title and become the new Yaemon. Clearly, he has already inherited the Yaemon spirit.

One of the most important steps in creating the traditional Yaemon flavour is the preparation of koji (Aspergillus oryzae), a fungus that play a key role in kick-starting the fermentation process. The quality of the koji is, according to Yaemon, one of the key factors in determining the taste of the final product. While many large industrial producers incubate koji at an artificially constant temperature to speed up production, Minamigura grow their koji in tune with the natural changing of the seasons, giving greater character and depth to the finished product. This, along with the continued use and maintenance of ancient wooden fermentation vats and their precious cultures of microorganisms, provides the essence of the Yaemon Tamari flavour.

“All we do is lay the groundwork,” says Yaemon. “After that, the work is done by the environment, so our role is to give nature a helping hand. For example, by keeping an eye on the maturation process. This is actually quite complex. We produce koji all year round, so we have to work hard to consistently get the same results. When it’s cold, we have to monitor the temperatures at which the koji is incubated very carefully, and when it’s hot, we have to take steps to prevent the incubation room from overheating. We monitor the koji constantly for 72 hours without taking our eyes off of it. This critical period will ultimately determine the taste and the quality of the finished product.”

He continues, “We are using very traditional methods to make our tamari, and the knowledge that we are producing something really special is what keeps us motivated. You will never achieve excellence if you start thinking that what you’re doing is just “good enough”. We never stop striving—for the best ingredients, of course, and for a product that contains nothing artificial—but we also strive to maintain our drive and our dedication to self-improvement. We are constantly aiming to produce something better.”

“We’re certainly not the cheapest product on the market”, acknowledges Yaemon. “I am full of appreciation for our customers. That’s what makes us carry on. We dare not betray their expectations, and I would be deeply ashamed if they told us that the taste of our tamari had changed, because maintaining the Yaemon flavour is my responsibility. I feel it is my mission as fifth generation brew-master to protect Yaemon Tamari.”

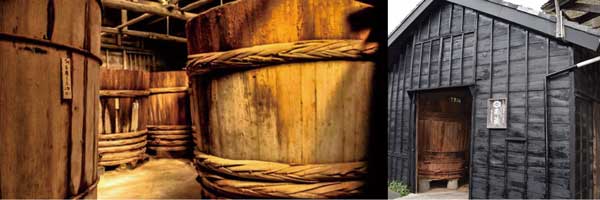

Tools of Tradition: The Storehouse and Cedar Vats

The Minamigura storehouse (kura) was built when the company was founded in 1871, and ever since then its wooden structure and earthen walls have provided an ideal environment for brewing tamari. During Japan’s punishing summer months, the kura keeps the temperature cooler inside than outside so that conditions remain optimal in spite of the heat.

In addition, both the storehouse and the cedar vats contain rich ecosystems of bacteria, which have developed over generations and are ideally suited to miso and tamari production. These bacteria play a vital role in the koji-making stage and also support fermentation and maturation, adding richness and depth to the tamari.

The Minamigura storehouse contains more than ninety cedar vats, many of which have been in use for over a hundred years. Around the beginning of the twentieth century, there were around fifty local tamari producers still in operation, and as a result the construction and sale of wooden vats was a flourishing local industry. However, the last local vat maker closed three years ago. “So we ordered twenty cedar vats,” says Yaemon, “all to be built within the final three years of business—we probably pushed them to their limits. The vats they made for us were recycled from the vats of producers who had closed, so they have been in constant use for nearly 150 years. We are determined to preserve these kinds of traditional methods and will continue to take care of our precious cedar vats for as long as we can.”

Yaemon’s Recommended Recipe

As long as you have quality ingredients, creating delicious dishes doesn’t have to be hard. The following recipe is super simple, yet a favorite of the Yaemon family. The key to the dish is, of course, the addition of tamari before cooking. This lifts the ingredients and enriches the dish with a deeply satisfying savory bass note.

Tamari Seasoned Rice with Vegetables

Serves 4

Ingredients

Ingredients

- 1 ½ carrots

- ½ block of konjac (devil’s tongue jelly; sold in solid blocks of approx. 220g)

- 1 bunch enoki mushrooms

- 4 dried shiitake mushrooms

- 2 slices of abura-age (a thin slice of deep-fried tofu)

- 100ml Mitoku Organic Yaemon Tamari

- 720ml water

- 720g rice

Preparation Method

- Soak the dried shiitake mushrooms in water for at least an hour. Wash the rice with fresh water until the water runs clear, drain, and leave to one side.

- Finely chop the carrots, konnyaku, shiitake and enoki mushrooms.

- If you have a rice cooker, place the washed rice in a rice cooker and add the vegetables and the tamari. Add water up to the 720ml (4 go) line and start the rice cooker on a “takikomi gohan (seasoned rice)” programme.

- If you do not have a rice cooker, place all the ingredients, including the washed rice and 720ml of water, in a pan on a high heat. Once the water has boiled, reduce the heat to low and allow to simmer for 10 mins. Turn the heat off and leave to sit with the lid on for a further 10 mins. Do not remove the lid at any time during the cooking or sitting.

- Open the rice cooker or remove the lid from the pan, and mix well. Garnish with a handful of mitsuba (Japanese wild parsley) or another fresh green herb of your choice.